일반 Size Pellet 그대로 투입가능한 11mm D 미니 트윈 압출기! Scale up 신뢰도 검증된 유일의 미니 트윈 압출기.

Save time and money developing formulations for polymer and food products with the Thermo Scientific™ Process 11 Parallel Twin-Screw Extruder. Use as little as 20 gm of material per experiment with this parallel co-rotating extruder to optimize your process parameters and formulation.

This lab bench extruder is ideal for a variety of compounding workflows with accessories such as: dies, 3D filament spooler, sheet take-off system, pelletizer, and a melt pump for Pulsation-free metering of melt that enables production suitable for filaments, sheet film or fiber spinning. Create test specimens using the Thermo Scientific™ HAAKE™ MiniJet Pro Injection Molding system for testing mechanical or optical properties. Choose from two Process 11 Extruders; standard or hygenic version for food applications (e.g., plant-based meat analogues).

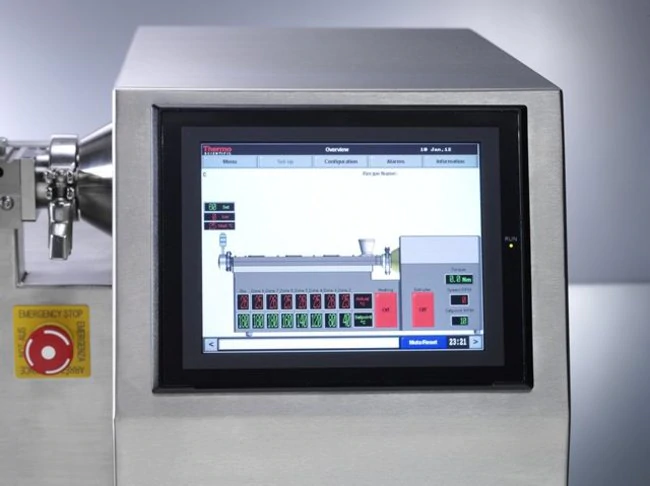

The Process 11 Parallel Twin-Screw Extruder was created with a user-friendly touch-screen operation that features an integrated feeder control and easily removable product contact parts. The compact monocoque design minimizes the usage of lab space and is ideal for fume hood applications. The screw elements and barrel design scale geometrically across all Thermo Scientific extruders and allow easy process scale-up.

The Process 11 Parallel Twin-Screw Extruder Features:

- Minimized sample material usage (20 g)

- Throughput range 20g/h to 2.5kg/h

- Small footprint bench top design that is easily transportable

- Segmented screw design with removable top half barrel

- Easy-to-operate touch screen with integrated feeder control

- Geometrically scalable screw and barrel design across portfolio

Recommended for:

Materials:

- Polymers

- Additives

- Adhesives

- Food

- Cosmetics

Applications:

- Compounding

- Masterbatches

- Nanocomposites

A small footprint reduces lab space requirements and lower ingredient consumption reduces environmental contamination and operator exposure.